The energy efficiency of our plants is particularly important to us. In the past, SAFED systems were already equipped with the latest available, future-oriented, energy and consumption-optimized solutions. We are consistently pursuing this path.

We support you with our many years of experience in the planning of new plants or in the optimization of existing plants. The savings in terms of energy and media consumption that can be achieved for you in this way bring you noticeable cost reductions. You also ensure sustainable, environmentally friendly and resource-conserving production in the interest of our future.

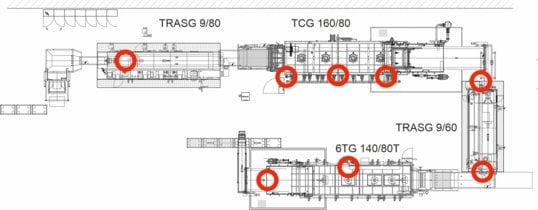

In-process heat recovery I

In-process heat recovery II

Immersion oilbath

Optimized wall insulation

ecoBOX - Reduction of the inert gas consumption